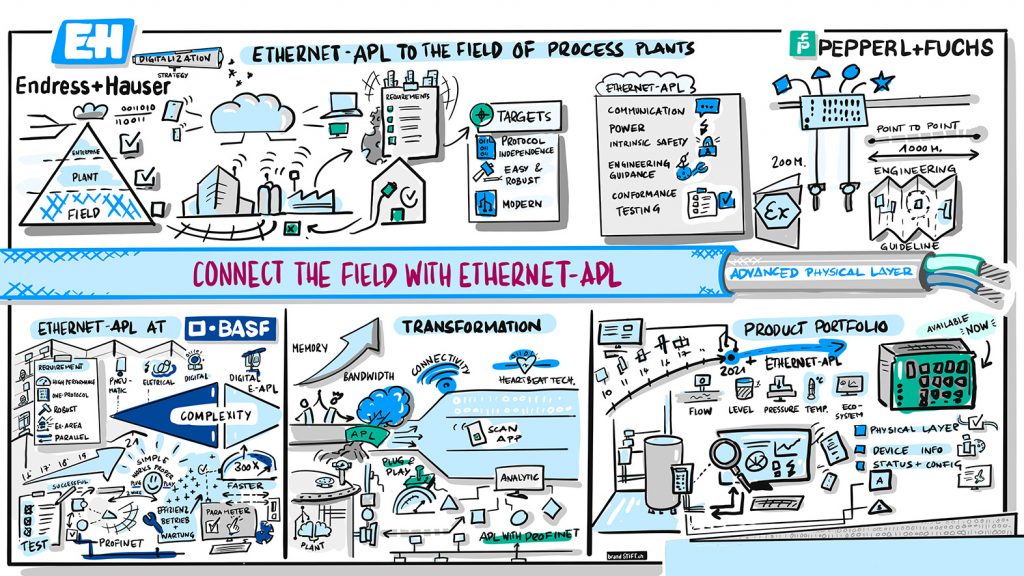

Digitalisation is offering industrial process plants the opportunity to network their instrumentation and gather data for analysis like never before. But established field technologies are limited in supporting the move to digital due to low bandwidth and speed or laborious protocol conversion. Now Ethernet-APL meets the growing requirements of the process industry, offering efficient engineering and plant design, fast commissioning, easier problem solving and reduced complexity.

Ethernet-APL has been developed by a group of leading suppliers, including Endress+Hauser, and standards development organisations in response to calls for a new open standard for use in process automation and instrumentation. The resulting technology, which has been proven in use in industry trials, provides easy access to field instrumentation independent of manufacturer, allowing long-distance connectivity even in hazardous areas. For plant operators looking to connect their devices and gather data for analysis, this is a huge step forward.

The new standard extends the use of established Ethernet-based communications from enterprise systems to the field, similar to a home network. As well as offering remote access to field devices, Ethernet can measure multiple variables from one device. Not only is it much quicker than fieldbus or traditional 4–20mA technology, with high-speed data transfer at 10 Mbps for real-time data access, it also simplifies operations through a reduction in wiring and additional hardware.

Simplifying networks

Ethernet-APL uses standard 2-wire cabling for easy integration into existing networks. Devices are automatically discovered over the network, so integration is simple and remote device configuration can be completed in seconds. There’s less hardware than with traditional systems and there’s no need to convert protocols.

In addition to connecting to a web server for simple device configuration, using an edge device you can transfer data from your devices into the cloud. Being able to access and utilise this data is key to managing today’s process plants, which are competing to produce more products with less waste. Thin profit margins require increased output yield with increasing quality, and this can be achieved by obtaining more plant data from process automation systems and instrumentation. Ethernet-APL allows you to harness the potential of analytics for predictive maintenance, fast troubleshooting and error finding.

Using Ethernet-APL

The first Endress+Hauser instruments with Ethernet-APL capability will be launched in spring 2022 with the full suite of products being available by the end of the year. As well as having obvious applications in new projects and plant upgrades, it is possible to retrofit Ethernet-APL to existing sites. As Ethernet-APL is protocol independent, existing industrial Ethernet protocols, such as Profinet, Ethernet IP and Modbus TCP, can be utilised, and any new industrial Ethernet protocols in the future would also make use of APL.

For more information, visit www.endress.com/apl or call us on 0161 286 5050.