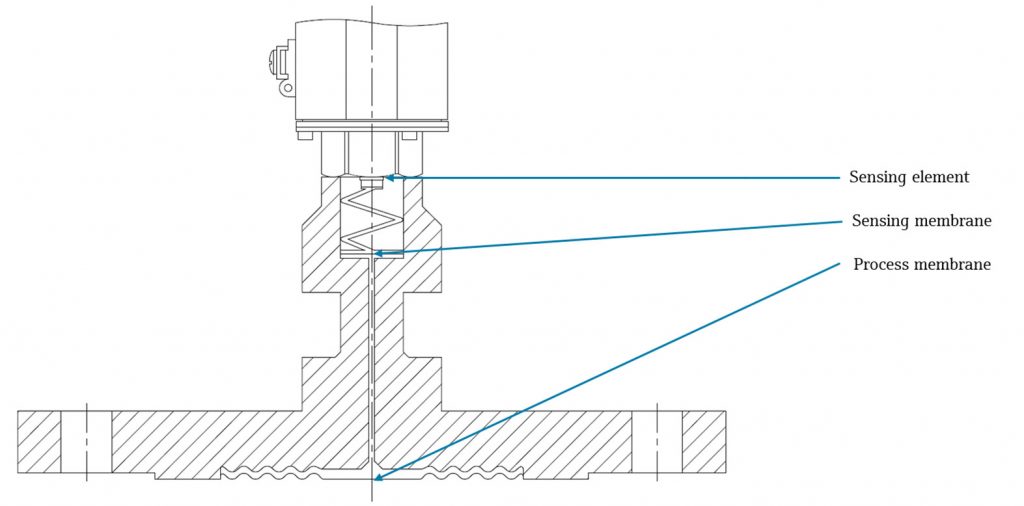

Pressure measurement is used widely in the process industry to monitor not only the process pressure in a vessel or pipeline but also level and even flow rate. To protect the pressure transmitter and its sensitive electronics from the harsh conditions of an industrial process, diaphragm seals are often used. While diaphragm seals are very useful in solving some challenging applications, their performance can be affected by temperature changes. Endress+Hauser’s TempC membrane can typically reduce these measurement errors by up to 90%, making processes more reliable and improving safety.

Applications requiring a diaphragm seal design are usually those with high process temperatures, aggressive media (in the form of physical abrasion or chemical reaction), strong process vibrations or a combination of all three.

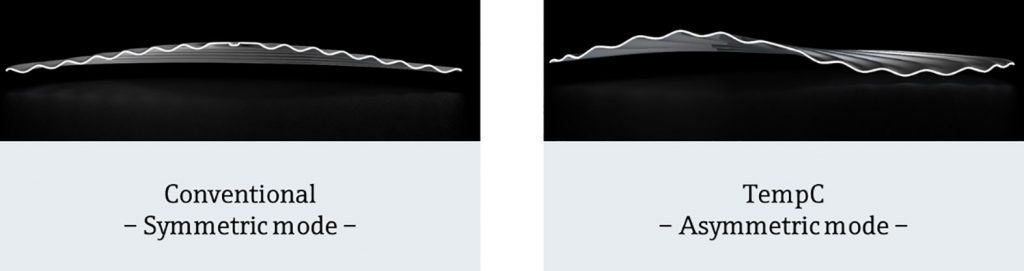

A diaphragm seal creates an oil-filled barrier between the pressure transmitter and the measured media. However, changes in process or ambient temperature can cause the oil in the system to expand or contract, leading to measurement errors. The TempC membrane is more flexible than traditional membranes, so it absorbs the change in volume, reducing any potential error. This increased sensitivity also results in a more accurate performance when measuring lower pressures, without the requirement to increase process membrane size.

Maximum process safety

TempC can be used in the temperature range -40°C to 250°C. This guarantees the highest degree of process safety, including in tanks and pipes that are cleaned or sterilised (CIP/SIP) at high temperatures, even for very long cycles. For aggressive media, the membrane can be created from materials such as Monel and tantalum for abrasion resistance or protection against chemicals.

To find out more about the TempC membrane, watch our video or visit www.uk.endress.com/tempc

For further reading please see: Electronic DP improves accuracy, installation and maintenance