John Pointon & Sons cuts gas, electricity and water bills

John Pointon & Sons provides waste disposal, recycling and environmental solutions for animal by-products and food waste. Every year, the company collects more than 300,000 tonnes of waste material, which it transforms into high-quality products destined for a range of industries in the United Kingdom and Europe. Customers include major pet food manufacturers, oleochemical industries and cement producers. The organisation employs more than 200 people across Staffordshire.

‘We’ve always sat down and talked about what is the next step, and that’s why I like working with Endress+Hauser. They look at your problem and work out how to get round it.’

Paul Latham, Energy Manager, John Pointon & Sons

The challenge

John Pointon & Sons operates the largest single-site rendering and recycling facility in the UK. The processes at this site in Cheddleton, Staffordshire, use a large amount of gas and other utilities and the company was struggling with reliable metering. I/O modules that were being used for energy monitoring were failing due to the corrosive site environment, leading to poor data collection and regular unplanned downtime. Inadequate software also meant the company couldn’t make good use of the data that was being recorded or assess where energy savings could be made.

John Pointon & Sons’ Energy Manager, Paul Latham, knew that action had to be taken to save money and prevent energy wastage. ‘Our gas bills were £5 million a year and our electricity bills £1.5 million, so if we could save a few per cent that’s many thousands of pounds,’ he says. A further financial incentive to save energy came in the form of an agreement with the gas supplier not to exceed usage of 1,250,000 kwh per day. As Paul Latham explains, ‘If we go over our allowance on just one day we get fined £100,000. We were nearly caught out with it when we initially had the new contract with the supplier because we hadn’t got good monitoring.’

The solution

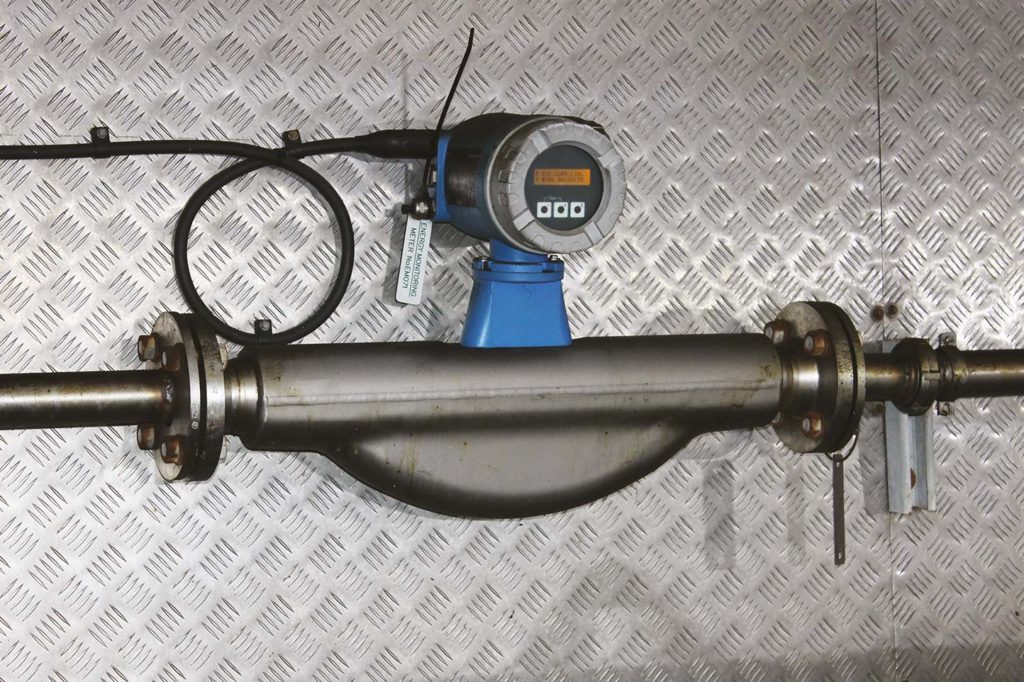

Endress+Hauser was brought in to carry out an energy efficiency assessment and supply a complete energy monitoring solution. As well as supplying T-mass, Prowirl, Promag and Promass flowmeters to monitor gas, water, steam and tallow (animal fat), Endress+Hauser installed a WirelessHART data collection system.

Data is now collected from a WirelessHART SWG70 gateway and stored within an Endress+Hauser data logger. Every 30 minutes, the data is sent to the cloud-based eSight energy management system. Chris Snelling, Wireless Business Development Manager for Endress+Hauser Ltd, says wireless was the obvious data collection solution due to the site’s harsh environment: ‘The plant didn’t have an Ethernet network and expensive input modules were getting corroded. Because our wireless modules are protected against ingress they just get attached directly to the instruments or on local junction boxes for several instruments.’

In later phases of the project, Endress+Hauser also supplied Deltabar differential pressure transmitters for odour abatement and a dissolved oxygen monitoring solution for the on-site water treatment plant. Unlike some other manufacturers, Endress+Hauser was also able to offer consultancy services to support the company with their Energy Savings Opportunity Scheme (ESOS) assessment, which is compulsory for all large businesses, and helped them to achieve ISO 50001 accreditation for energy management.

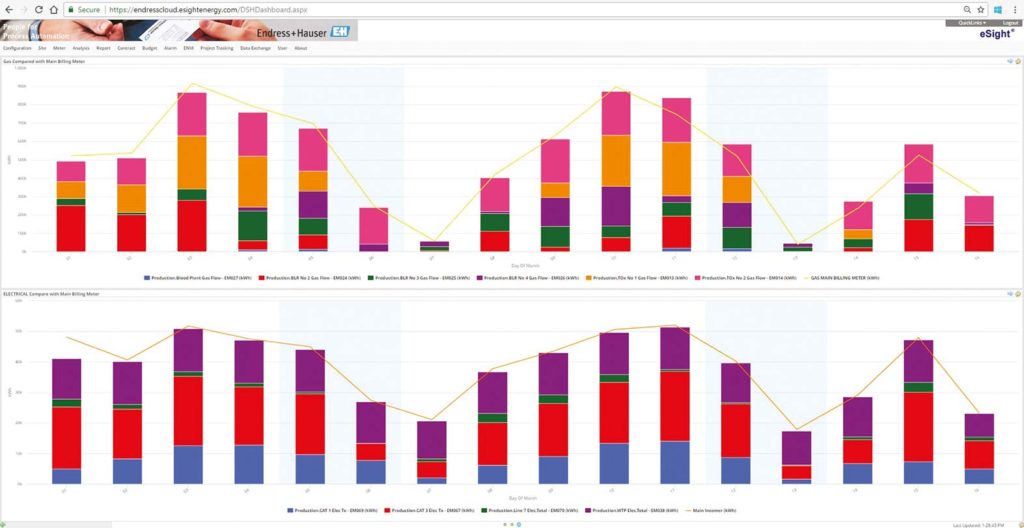

eSight software uses data from the meters to provide a continuous check on how much energy is being used around the site in different production lines and processes. ‘Initially I’d asked an IT company to provide us with some sort of monitoring application, but it was total rubbish,’ says Paul Latham. ‘I got talking to Endress+Hauser and they provided us with a free trial of eSight. It’s really good. You can manipulate all your data and generate useful reports.’

The benefits

The company exceeded its target of saving 5% gas and electricity in 2017, which equates to a cost saving of more than £400,000, and is hoping to achieve a further 2.5% reduction in 2018. Paul Latham says they’re more in control of problems now they can identify them quickly: ‘We used to just pay the bill and that was it. Now we look at how the energy is being used and we can see trends. We use eSight to prepare a weekly report and the graphs make it easy to see if you’ve got an issue somewhere. Just recently we went sky high with our kilowatts per tonne and we were able to identify a problem with the valves on the cookers which meant the steam was being wasted. We probably wouldn’t have known about it before this system was installed. Now I know exactly where the problem is and we can get on top of it.’

Apart from the cost-saving benefits, achieving ISO 50001 accreditation shows that John Pointon & Sons takes energy management seriously. ‘I’ve just had my second-year audit and that’s gone through without any issues so we’ve done really well,’ confirms Paul Latham. ‘Having ISO 50001 is a good way of proving your credentials to customers in this country and abroad.’

Further phases of the energy management project are planned, using the data from eSight to calculate potential savings and assess the best course of action. Paul Latham says, ‘We’ve always sat down and talked about what is the next step, and that’s why I like working with Endress+Hauser. They look at your problem and work out how to resolve it.’

For more information please email sales@uk.endress.com or call us on 0161 286 5050